The Microprocessor

November 5, 2012 Leave a comment

The Derby Timer uses the ATMega168 microprocessor. This processor was included in the NerdKits package that I purchased online at http://www.nerdkits.com. The NerdKits package includes the processor, a breadboard, USB cable, LCD display, and some miscellaneous parts. Most importantly, the NerdKits package includes a .pdf manual that explained how to put the microprocessor together. Since the Derby Timer was my first microprocessor project, the NerdKits manual was an invaluable help. It was definitely money well spent.

The basic NerdKits package is meant for educational use, not an assembled project. (It would be a bad idea to have a breadboard with jumpers banging around the derby timer!) Since I now had practice programming the ATMega168 included in the NerdKits, I then purchased a printed circuit board kit from ProtoStack at http://www.protostack.com/boards/microcontroller-boards/atmega168a-development-kit, that uses the same processor technology.

Although the NerdKits and ProtoStack kits use the same microprocessor technology, there is an important difference in how they are programmed. The NerdKits processor comes with a bootloader program pre-installed, while the ProtoStack processor does not. The pre-installed bootloader allows the NerdKits processor to be programmed with the USB cable that comes included with the kit. The ProtoStack processor requires a separate programmer. There are some pros and cons to each method that I will cover in another post. (Since I had not yet purchased a programmer, I was able to use the ATMega168 supplied with the NerdKits in the ProtoStack board and program it successfully using the NerdKits supplied USB cable.)

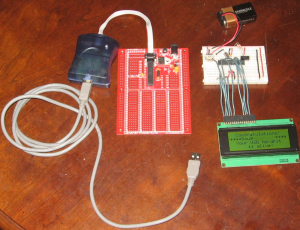

For illustration purposes, here is a picture of the ProtoStack next to the NerdKits. The ProtoStack is the red circuit board on the left. There is an AVRISP mkII programmer (looks like a small mouse) plugged into it. The NerdKits is on the right. Note the green LCD display that comes with the NerdKits.

(Disclaimer: This picture does not include all of the parts included with either kit.)